Dye Penetrant Inspection

SWA offers dye penetrant testing in Perth, Regional WA and Offshore.

Dye Penetration Testing Perth

DPI is a widely used to check for surface breaking flaws in defects that can not be seen with visual inspections. Unlike MPI it can be used on non-ferromagnetic components.

Key features

- Preventing failures that occur from flawed parts making it into assemblies without prior inspection.

- Compliance to fabrication construction codes.

- NATA accredited testing facility

- Suitable for testing near surface defects in ferromagnetic materials.

- Remote testing of welds and structure.

- Testing of Gears and machined components.

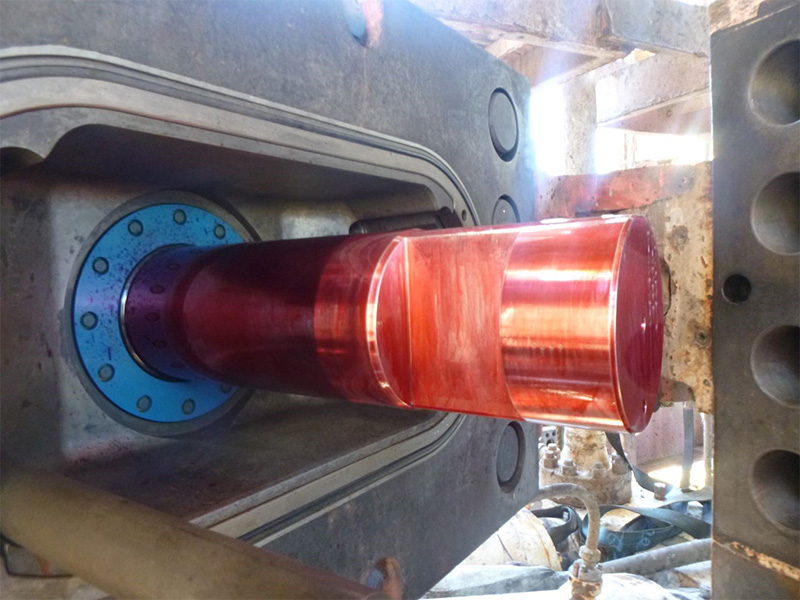

Dye Penetrant Inspection (DPI/ PT)

Dye Penetrant Inspection (DPI/PT) is widely used to detect surface breaking flaws.

This non-destructive testing technique, also known as liquid penetrant inspection (LPI), is a cost-effective method used to locate surface breaking flaws such as cracks, porosity, laps, seams and other surface discontinuities.

Dye penetrant inspection can be applied to both ferrous and non-ferrous materials and all non-porous materials (metals, plastics or ceramics). This method does not detect subsurface discontinuities like MPI.

It is commonly used to detect defects in weldments, castings and forgings. This method is also useful for testing on-site as it is portable, and when applying certain techniques such as visible color contrast there is no need for additional resources such as electricity or water. This makes it a highly convenient and effective for inspecting surface discontinuities.

Dye Penetration Testing in Perth, Regional WA and Offshore.

We provide a range of dye penetration testing and inspection services to fabrication workshops, commercial, industrial, mining/ processing plants, refineries, marine and offshore facilities.