Eddy Current Inspection

SWA offers Eddy Current Testing in Perth, WA, NT and offshore locations

Eddy Current Testing Perth

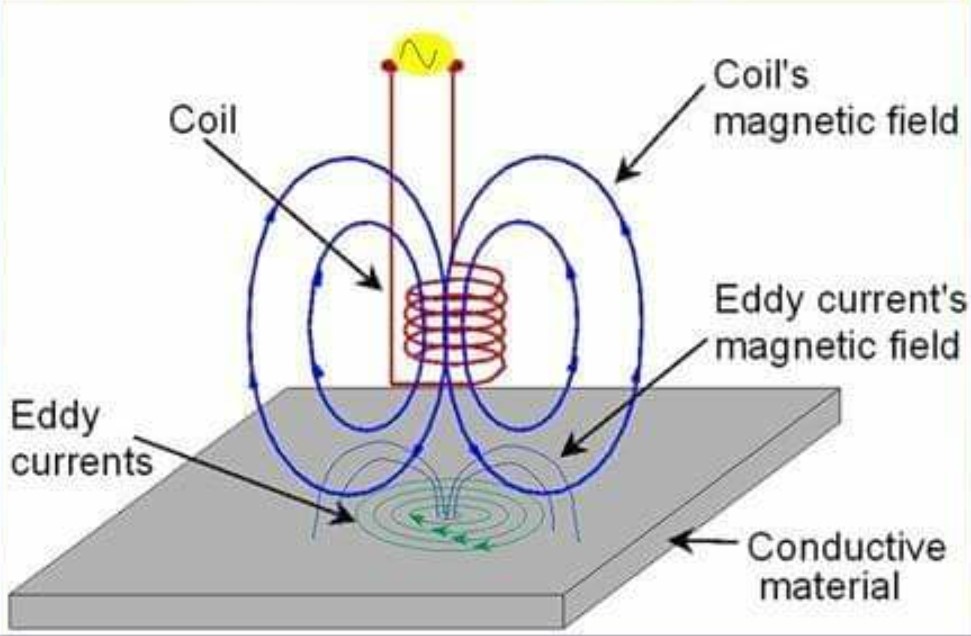

ECI uses to process of electromagnetic induction through a probe using alternating current through a coil to generate a magnetic field.

ECI is used by detecting a change of impedance and can be used to inspect welds and structure through a coating to eliminate the need for paint/coating removal.

Eddy Current Inspections

Eddy Current Inspections use a coil of the conductive wire that is excited with an alternating electrical current. This wire coil produces an alternating magnetic field around itself.

The magnetic field oscillates at the same frequency as the current running through the coil. When the coil approaches a conductive material, currents opposite to the ones in the coil are induced in the material causing an impedance on the digital display.

Eddy Current Inspections are most common in the oil and gas industry and with inspections of in-service equipment due to its ability to inspect coated materials without the need for paint removal and re-application. This results in a much more time-efficient manner and reduction of additional hazards associated with paint removal and application of paint.

Variations in the electrical conductivity and magnetic permeability of the test object, and the presence of defects cause a change in eddy current and a corresponding change in phase and amplitude that can be detected by measuring the impedance changes in the coil, which is a telltale sign of the presence of defects.

This is the basis of the standard used in modern Eddy Current kits.

Eddy Current Testing in Perth, WA & NT

ECI has a very wide range of applications. Since ECI is electrical in nature, it is limited to a conductive material. There are also physical limits to generating eddy currents and depth of penetration.

At present, we offer a variety of our inspection and testing services to industries in Perth, WA, NT and offshore.