Services

SWA have a range of services to offer to make your workplace safe and more cost effective.

Ultrasonic Thickness Testing

UT Thickness works by measuring the time of pulse-echo from a probe through a material to determine the thickness and determine wall loss and assess for internal laminations.

Magnetic Particle Inspections

MPI is used to detect surface and slightly subsurface flaws in most ferromagnetic materials that can not normally be seen from visual inspections.

Dye Penetrant Inspections

DPI is a widely used to check for surface breaking flaws in defects that can not be seen with visual inspections. Unlike MPI it can be used on non-ferromagnetic components.

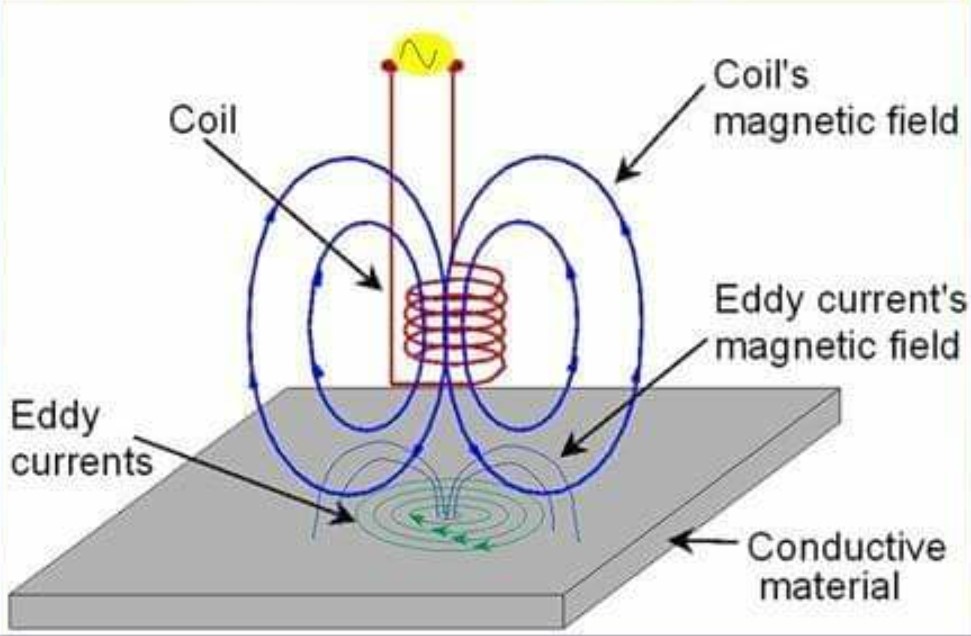

Eddy Current Inspections

ECI uses to process of electromagnetic induction through a probe using alternating current through a coil to generate a magnetic field.

ECI is used by detecting a change of impedance and can be used to inspect welds and structure through a coating to eliminate the need for paint/coating removal.

Rope Access

All our technicians are trained to IRATA standards and require ongoing training to keep a high standard of quality and safety.

All rope access teams are led by a level 3 with the knowledge and experience to provide access and perform rescues in any scenario. Rope access personnel can be utilized as standby rescue teams in high risk jobs involved confined spaces and working at heights.

Proof Load Testing/ Pull Test

SWA offers proof load testing of lifting equipment and pull testing on anchor/lifting points. A proof load test helps to ensure that the equipment is up to the task, by verifying that there are no material or welding flaws, or other fundamental mechanical defects. By performing a proof load test, SWA can help to ensure that your lifting equipment is safe and reliable.

Lifting Equipment Inspection

At SWA we tag and log all your lifting and rigging equipment for compliance to relevant Australian Standards and following LEEA guidelines . This can be performed via rope access if needed to eliminate or minimise manual handling.

With regular independent audits and ongoing training we can guarantee the integrity of all lifting equipment inspections & record keeping is kept to the highest standard.

Dropped Object Prevention Scheme (DROPS) surveys

Our technicians can perform NDT on potential structural related dropped objects to determine the likelihood and recommendations.